| Availability: | |

|---|---|

| Quantity: | |

Project introduction

In order to improve coal mine production, large amounts of ventilation are usually used to discharge coal mine gas (called Ventilation Air Methane, or VAM for short). The concentration of methane in mine ventilation is very low (generally less than 1%), and the concentration fluctuation range is large. Its direct use as the main fuel is restricted. Almost all coal mines do not try to recover and treat the methane in mine ventilation, but directly use it. Emitted into the atmosphere, causing serious pollution problems to the atmospheric environment.

In view of the characteristics of huge coal mine ventilation air volume, very low gas concentration in coal mine ventilation air, and large fluctuation ranges of ventilation air volume and gas concentration, coal mine ventilation gas utilization technology was developed, and a vertical ventilation air thermal countercurrent oxidation device was developed for treatment. And use mine ventilation gas to reduce methane greenhouse gas emissions caused by coal mine production, while recovering and utilizing the energy in mine ventilation.

my country's research on the utilization technology of coal mine ventilated air gas started relatively late. In recent years, many domestic universities and colleges have conducted laboratory research on the mechanisms of catalytic oxidation and thermal countercurrent oxidation of ventilated air gas. However, no one that can truly demonstrate operation has been developed. Industrial prototype.

In 2007, Zibo Zichai New Energy Co., Ltd. cooperated with universities and colleges to jointly develop a vertical vent gas thermal countercurrent oxidation device. The 40,000m3/h vertical vented air thermal countercurrent oxidation device jointly developed by both parties underwent simulated vented air operation tests at the factory in the first half of 2009. The project passed the appraisal and acceptance organized by the Shandong Provincial Economic and Information Technology Commission in December 2009.

In 2010, a 40,000m3/h ventilated air oxidation device was put into on-site testing and demonstration operation in the coal mine.

Our company also undertook the key project of the National High-tech Research and Development Plan (863 Plan) 'Development of Key Technologies and Equipment for Separation and Oxidation Utilization of Coal Mine Ventilated Air Gas'. According to the project plan, we developed a 60,000m3/h vertical ventilated air oxidation device. .

Basic principles of coal mine vent gas thermal countercurrent oxidation device

The ventilated air gas thermal countercurrent oxidation device is mainly composed of five major parts: the oxidation device body, the gas inlet and outlet distribution system, the heating starting system, the ventilated air reversing system, and the real-time measurement and control system.

The external heat source (burner) heats the solid oxidation bed of the heat exchange medium to the methane oxidation temperature, introduces the ventilation gas from the mine into the oxidation device, and conducts heat exchange with the heat exchange medium in the device in the reaction zone. The gas is heated to the temperature required for gas combustion. , an oxidation reaction (combustion) occurs and heat is released. After the oxidation reaction is self-sustaining, external heating is stopped. One cycle includes two air flow reversals, and the control system automatically controls the reversal time and other parameters.

Main technical parameters

Gas concentration range for stable operation: 0.3% ~ 2.0%;

Methane oxidation rate ≥97%;

Able to generate superheated steam, the pressure of superheated steam is ≥2.5MPa, the temperature is ≥400℃, and the pressure and temperature fluctuation range is ±5%;

The gas resistance loss at the inlet and outlet is ≤4000Pa.

Main technical features of Zichai Coal Mine ventilated gas thermal countercurrent oxidation device

The vertical structure is adopted to avoid uneven temperature distribution caused by natural convection.

No catalyst is used, which avoids the problem of catalyst poisoning caused by hydrogen sulfide contained in mine ventilation.

A variety of honeycomb ceramic combined oxidation bed structures are used to improve the oxidation efficiency of vent gas, ensure the stable operation of the oxidation device, reduce the gas flow resistance, and extend the service life of the oxidation device.

The gas inlet and outlet distribution technology is adopted, and the flow guide is used to adjust the gas flow in and out of the oxidation bed everywhere to ensure that the exhausted air enters the oxidation bed evenly.

The external heat source uses a burner, which can save a lot of electrical energy compared with traditional electric heating.

The constant-temperature high-temperature heat source is used to exchange heat with the heat exchanger to produce superheated steam, thereby avoiding fluctuations in superheated steam parameters and improving steam quality.

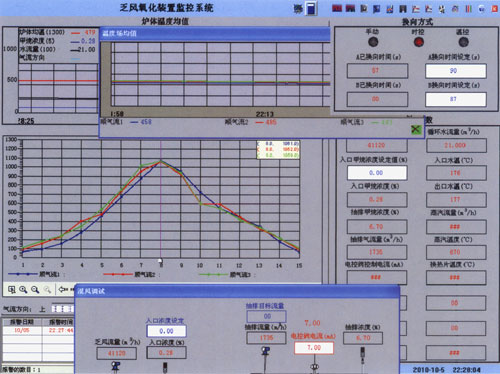

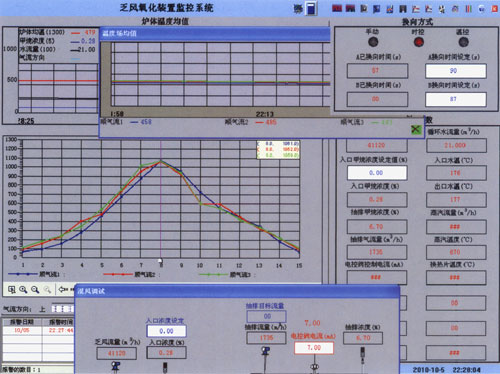

The high-reliability computer monitoring system centrally controls each subsystem of the device and performs systematic coordination to ensure the safe and normal operation of the thermal countercurrent oxidation device.

Economic benefit analysis

Ventilated air gas undergoes an oxidation reaction to convert CH4 into CO2, reducing greenhouse gas emissions. It can apply for CDM projects and bring huge economic benefits; the heat generated by the reaction can be used for heating or power generation, which will also produce good economic benefits.

For example: Assume that the methane concentration of mine exhaust air is 0.8%, the flow rate is 80,000 m3/h, the investment is about 11 million, the annual mine exhaust air treatment is 700.8 million m3, the annual greenhouse gas emission reduction is 80,000t C02 equivalent, and the annual heat recovery is 149666.4 GJ. The annual power generation is about 10 million kilowatt hours.

According to the 'Kyoto Protocol', methane carbon sink trading (CDM) was implemented in 2008. If you apply for a CDM project, calculated at US$15/tC02, the income from the carbon sink indicator alone can reach US$1.2 million per year.

Project introduction

In order to improve coal mine production, large amounts of ventilation are usually used to discharge coal mine gas (called Ventilation Air Methane, or VAM for short). The concentration of methane in mine ventilation is very low (generally less than 1%), and the concentration fluctuation range is large. Its direct use as the main fuel is restricted. Almost all coal mines do not try to recover and treat the methane in mine ventilation, but directly use it. Emitted into the atmosphere, causing serious pollution problems to the atmospheric environment.

In view of the characteristics of huge coal mine ventilation air volume, very low gas concentration in coal mine ventilation air, and large fluctuation ranges of ventilation air volume and gas concentration, coal mine ventilation gas utilization technology was developed, and a vertical ventilation air thermal countercurrent oxidation device was developed for treatment. And use mine ventilation gas to reduce methane greenhouse gas emissions caused by coal mine production, while recovering and utilizing the energy in mine ventilation.

my country's research on the utilization technology of coal mine ventilated air gas started relatively late. In recent years, many domestic universities and colleges have conducted laboratory research on the mechanisms of catalytic oxidation and thermal countercurrent oxidation of ventilated air gas. However, no one that can truly demonstrate operation has been developed. Industrial prototype.

In 2007, Zibo Zichai New Energy Co., Ltd. cooperated with universities and colleges to jointly develop a vertical vent gas thermal countercurrent oxidation device. The 40,000m3/h vertical vented air thermal countercurrent oxidation device jointly developed by both parties underwent simulated vented air operation tests at the factory in the first half of 2009. The project passed the appraisal and acceptance organized by the Shandong Provincial Economic and Information Technology Commission in December 2009.

In 2010, a 40,000m3/h ventilated air oxidation device was put into on-site testing and demonstration operation in the coal mine.

Our company also undertook the key project of the National High-tech Research and Development Plan (863 Plan) 'Development of Key Technologies and Equipment for Separation and Oxidation Utilization of Coal Mine Ventilated Air Gas'. According to the project plan, we developed a 60,000m3/h vertical ventilated air oxidation device. .

Basic principles of coal mine vent gas thermal countercurrent oxidation device

The ventilated air gas thermal countercurrent oxidation device is mainly composed of five major parts: the oxidation device body, the gas inlet and outlet distribution system, the heating starting system, the ventilated air reversing system, and the real-time measurement and control system.

The external heat source (burner) heats the solid oxidation bed of the heat exchange medium to the methane oxidation temperature, introduces the ventilation gas from the mine into the oxidation device, and conducts heat exchange with the heat exchange medium in the device in the reaction zone. The gas is heated to the temperature required for gas combustion. , an oxidation reaction (combustion) occurs and heat is released. After the oxidation reaction is self-sustaining, external heating is stopped. One cycle includes two air flow reversals, and the control system automatically controls the reversal time and other parameters.

Main technical parameters

Gas concentration range for stable operation: 0.3% ~ 2.0%;

Methane oxidation rate ≥97%;

Able to generate superheated steam, the pressure of superheated steam is ≥2.5MPa, the temperature is ≥400℃, and the pressure and temperature fluctuation range is ±5%;

The gas resistance loss at the inlet and outlet is ≤4000Pa.

Main technical features of Zichai Coal Mine ventilated gas thermal countercurrent oxidation device

The vertical structure is adopted to avoid uneven temperature distribution caused by natural convection.

No catalyst is used, which avoids the problem of catalyst poisoning caused by hydrogen sulfide contained in mine ventilation.

A variety of honeycomb ceramic combined oxidation bed structures are used to improve the oxidation efficiency of vent gas, ensure the stable operation of the oxidation device, reduce the gas flow resistance, and extend the service life of the oxidation device.

The gas inlet and outlet distribution technology is adopted, and the flow guide is used to adjust the gas flow in and out of the oxidation bed everywhere to ensure that the exhausted air enters the oxidation bed evenly.

The external heat source uses a burner, which can save a lot of electrical energy compared with traditional electric heating.

The constant-temperature high-temperature heat source is used to exchange heat with the heat exchanger to produce superheated steam, thereby avoiding fluctuations in superheated steam parameters and improving steam quality.

The high-reliability computer monitoring system centrally controls each subsystem of the device and performs systematic coordination to ensure the safe and normal operation of the thermal countercurrent oxidation device.

Economic benefit analysis

Ventilated air gas undergoes an oxidation reaction to convert CH4 into CO2, reducing greenhouse gas emissions. It can apply for CDM projects and bring huge economic benefits; the heat generated by the reaction can be used for heating or power generation, which will also produce good economic benefits.

For example: Assume that the methane concentration of mine exhaust air is 0.8%, the flow rate is 80,000 m3/h, the investment is about 11 million, the annual mine exhaust air treatment is 700.8 million m3, the annual greenhouse gas emission reduction is 80,000t C02 equivalent, and the annual heat recovery is 149666.4 GJ. The annual power generation is about 10 million kilowatt hours.

According to the 'Kyoto Protocol', methane carbon sink trading (CDM) was implemented in 2008. If you apply for a CDM project, calculated at US$15/tC02, the income from the carbon sink indicator alone can reach US$1.2 million per year.