300 series gas generator set

my country's coalbed methane (commonly known as gas) resources are very rich. Below the surface, there are 35 trillion cubic meters of gas contained in coal seams with a depth of more than 2,000 meters, which is basically equivalent to my country's natural gas resources and equivalent to 42 billion tons of standard coal. In 2006, China has included the development of coalbed methane in the 'Eleventh Five-Year Plan' energy development plan, and the industrialization of coalbed methane has ushered in a good opportunity for development.

The 300 series gas engine is a gas engine independently developed by Zibo Zichai New Energy Co., Ltd. It uses coal mine gas as the main fuel and has advanced technology. It has the characteristics of compact structure, simple operation, reasonable layout and easy maintenance. Each type of unit is mainly for land-based power generation. The frequency can be divided into 50Hz and 60Hz. It can operate as a single unit or multiple units in parallel. It has been widely used in large domestic coal mines.

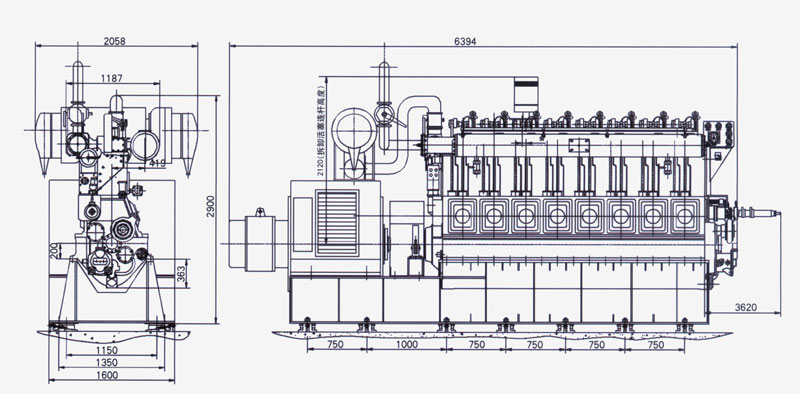

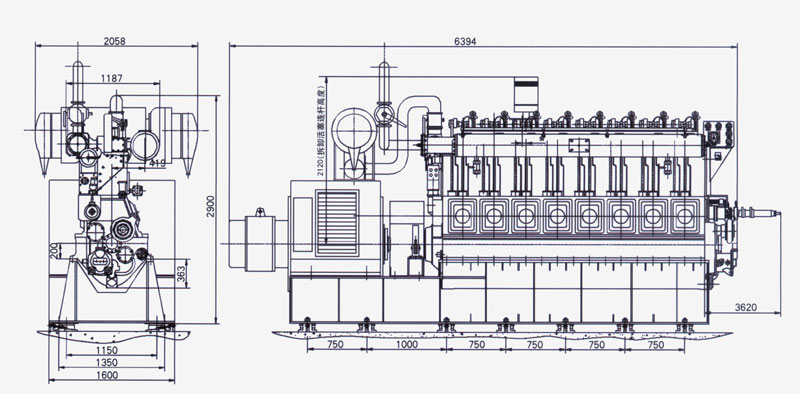

8300 gas generator set outline drawing

Technical characteristics of Zichai generator set

It has the advantages of large cylinder diameter, long stroke and large power reserve. It is suitable for the characteristics of large fluctuations in coal bed methane gas source and can ensure that the output power of the unit remains constant.

It is suitable for a wide range of gas concentration, and the low-concentration unit has outstanding advantages.

The low speed of the generator set reduces engine wear, extends the service life of parts, and reduces the reserve of spare parts.

Coalbed Methane Engine has developed a gas engine intelligent management system, which can ensure the operation of the gas engine and enable remote monitoring of the gas engine unit.

Gas engines use electronic control methods to improve the engine's power and economy.

The exhaust pipe adopts a water-cooled structure, with low exhaust temperature, sufficient combustion, and uniform exhaust temperature in each cylinder.

The ignition system produced by the American ALTRONIC company is used to obtain high ignition heat and ignition time to ensure ignition reliability.

Multiple lines of defense have been set up to ensure coalbed methane pipeline transportation.

Design an exhaust gas waste heat utilization system to fully utilize the heat of high-temperature flue gas to achieve combined heating, power and cooling, so that the total heat utilization rate of the burned gas reaches more than 70%.

It can output high, medium and low voltages to meet the different needs of users, avoid the initial investment of purchasing transformers, reduce copper losses and reduce operating costs.

Conditions of use

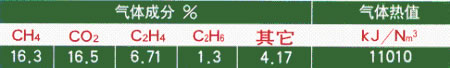

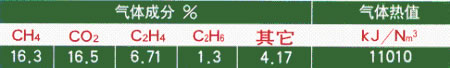

1) The gas composition and calorific value are as follows:

2) Air source conditions:

Gas delivery pressure 5-15kpa, pressure change rate ≤1kPa/min, change rate ≤5%/min, impurity particle size ≤5μm, impurity content ≤30mg/Nm3, moisture content ≤40mg/Nm3, free water not included, gas temperature ≤40℃, sulfur content ≤20mg/Nm3.

300 series gas generator set

my country's coalbed methane (commonly known as gas) resources are very rich. Below the surface, there are 35 trillion cubic meters of gas contained in coal seams with a depth of more than 2,000 meters, which is basically equivalent to my country's natural gas resources and equivalent to 42 billion tons of standard coal. In 2006, China has included the development of coalbed methane in the 'Eleventh Five-Year Plan' energy development plan, and the industrialization of coalbed methane has ushered in a good opportunity for development.

The 300 series gas engine is a gas engine independently developed by Zibo Zichai New Energy Co., Ltd. It uses coal mine gas as the main fuel and has advanced technology. It has the characteristics of compact structure, simple operation, reasonable layout and easy maintenance. Each type of unit is mainly for land-based power generation. The frequency can be divided into 50Hz and 60Hz. It can operate as a single unit or multiple units in parallel. It has been widely used in large domestic coal mines.

8300 gas generator set outline drawing

Technical characteristics of Zichai generator set

It has the advantages of large cylinder diameter, long stroke and large power reserve. It is suitable for the characteristics of large fluctuations in coal bed methane gas source and can ensure that the output power of the unit remains constant.

It is suitable for a wide range of gas concentration, and the low-concentration unit has outstanding advantages.

The low speed of the generator set reduces engine wear, extends the service life of parts, and reduces the reserve of spare parts.

Coalbed Methane Engine has developed a gas engine intelligent management system, which can ensure the operation of the gas engine and enable remote monitoring of the gas engine unit.

Gas engines use electronic control methods to improve the engine's power and economy.

The exhaust pipe adopts a water-cooled structure, with low exhaust temperature, sufficient combustion, and uniform exhaust temperature in each cylinder.

The ignition system produced by the American ALTRONIC company is used to obtain high ignition heat and ignition time to ensure ignition reliability.

Multiple lines of defense have been set up to ensure coalbed methane pipeline transportation.

Design an exhaust gas waste heat utilization system to fully utilize the heat of high-temperature flue gas to achieve combined heating, power and cooling, so that the total heat utilization rate of the burned gas reaches more than 70%.

It can output high, medium and low voltages to meet the different needs of users, avoid the initial investment of purchasing transformers, reduce copper losses and reduce operating costs.

Conditions of use

1) The gas composition and calorific value are as follows:

2) Air source conditions:

Gas delivery pressure 5-15kpa, pressure change rate ≤1kPa/min, change rate ≤5%/min, impurity particle size ≤5μm, impurity content ≤30mg/Nm3, moisture content ≤40mg/Nm3, free water not included, gas temperature ≤40℃, sulfur content ≤20mg/Nm3.