1. Introduction to 300 series biomass gas generator sets

my country's biomass energy resources are quite abundant. The resources of various agricultural wastes (such as straw, etc.) are equivalent to 308 million tons of standard coal every year, and the amount of firewood resources is equivalent to 130 million tons of standard coal. Therefore, it is necessary to use modern technology to develop and utilize Biomass energy is of great significance for establishing a sustainable energy system, promoting social and economic development and improving the ecological environment.

The 300 series biomass gas engine uses waste rice husks, straw, wood powder, wood chips, etc. as raw materials. It is burned and gasified in a gas generator to produce combustible power fuel to drive the engine. This kind of development and utilization of rice husk, straw, wood powder, sawdust, etc. instead of expensive and tight petroleum resources has good comprehensive economic benefits, and at the same time, it can consume a large amount of rice husk and straw to pollute the environment.

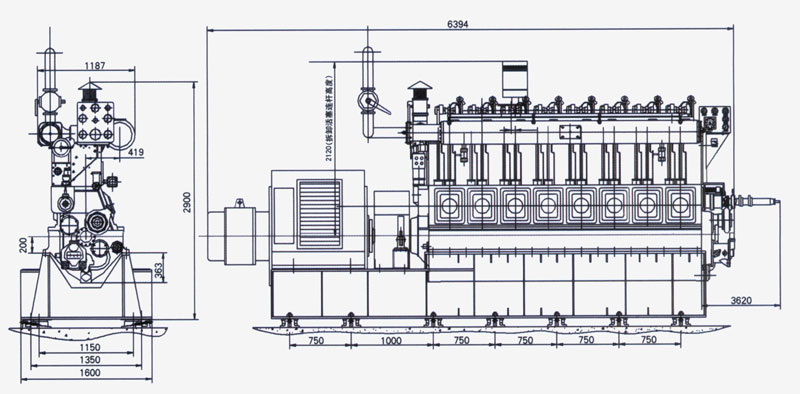

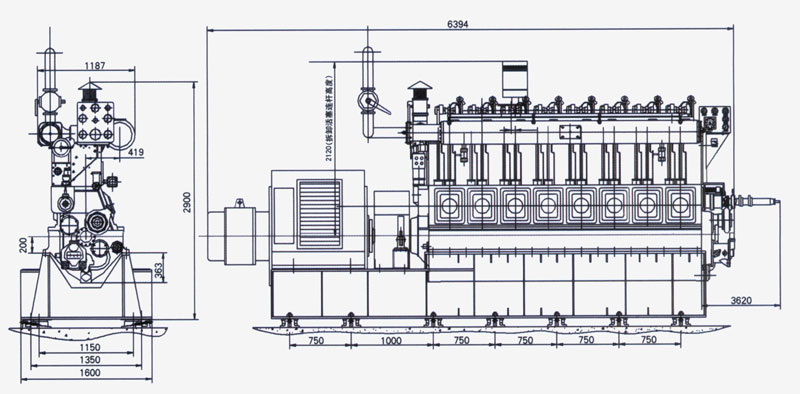

According to the combustion characteristics of biomass gas, low calorific value (about 4MJ/Nm3), and high tar, our company combines the characteristics of the 8300 diesel engine with large bore and long stroke, cooperates with relevant institutes, and uses its circulating fluidized bed gasifier technology , successfully developed the 8300 biomass gas engine, which has the characteristics of compact structure, simple operation, reasonable layout, and easy maintenance.

Each type of unit is mainly based on land-based origin. The frequency can be divided into 50HZ and 60HZ. It can be operated by a single unit or multiple units.

2. Technical characteristics

The gas mixing device uses a Vendry tube mixer or an electronically controlled mixer, with correct gas distribution timing and a reasonable ignition advance angle to facilitate the full combustion of combustible gas.

A reasonable air intake system makes air and gas mix more evenly, burn more fully, and improve gas utilization. Explosion-proof doors are installed at both ends of the air intake pipe.

The intake pipe is designed to reduce tar condensation in the intake pipe and has good maintainability.

Reasonably design the cam line type and select reasonable intake and exhaust timing to control the opening time and overlap angle of the intake and exhaust valves within a reasonable range, which can not only reduce the risk of intake pipe backfire, but also ensure the corresponding A certain degree of scavenging is beneficial to reducing the exhaust temperature.

The exhaust pipe adopts a water-cooling structure to reduce the temperature around the generator.

The ignition system produced by the American ALTRONIC company is used to obtain high ignition energy and ignition time, ensure the reliability of ignition, and meet the ignition needs of biomass energy.

3. Main advantages of 300 series biomass gas generating units

High power. The power of the unit can reach 550kW, which is more than twice the current high power in the domestic market, and can better meet the complete set needs of large-scale power stations.

High reliability. The prototype of this unit is a 8300 medium-speed diesel engine with mature domestic technology (maximum power 1103kW/600rpm). The power of the gas engine is relatively low, and the corresponding mechanical load is much smaller than the diesel engine specification, so the reliability is high.

Save material consumption. When the load of an 8300 biomass engine is 400kW, compared with two 200kW units when the load is (190+190)kW, it saves about 5% of materials, reduces the cost of power generation, and shows good economics.

The cylinder exhaust temperature is relatively low. Compared with the existing domestic 200kW unit, the exhaust temperature is 60~90~C lower. The thermal load of the engine is greatly reduced, the service life of valves and other components is extended, and the reliability of the entire machine is further improved.

4. Conditions of use

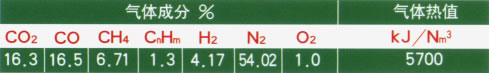

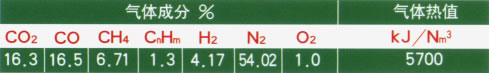

1) The gas composition and calorific value are as follows:

Gas composition and calorific value table

Gas composition and calorific value table

2) Air source conditions:

Biomass gas should undergo appropriate filtration, gas-liquid separation, and pressure stabilization before use. If the temperature is too high, it should be cooled and ensure that there is no liquid component in the gas. Pressure change rate ≤1kPa/min, tar content ≤20mg/Nm3, hydrogen volume content ≤15%, impurity particle size ≤5μm, moisture content ≤20mg/Nm3, impurity content ≤30mg/Nm3.

Aerial view of biomass power plant

1. Introduction to 300 series biomass gas generator sets

my country's biomass energy resources are quite abundant. The resources of various agricultural wastes (such as straw, etc.) are equivalent to 308 million tons of standard coal every year, and the amount of firewood resources is equivalent to 130 million tons of standard coal. Therefore, it is necessary to use modern technology to develop and utilize Biomass energy is of great significance for establishing a sustainable energy system, promoting social and economic development and improving the ecological environment.

The 300 series biomass gas engine uses waste rice husks, straw, wood powder, wood chips, etc. as raw materials. It is burned and gasified in a gas generator to produce combustible power fuel to drive the engine. This kind of development and utilization of rice husk, straw, wood powder, sawdust, etc. instead of expensive and tight petroleum resources has good comprehensive economic benefits, and at the same time, it can consume a large amount of rice husk and straw to pollute the environment.

According to the combustion characteristics of biomass gas, low calorific value (about 4MJ/Nm3), and high tar, our company combines the characteristics of the 8300 diesel engine with large bore and long stroke, cooperates with relevant institutes, and uses its circulating fluidized bed gasifier technology , successfully developed the 8300 biomass gas engine, which has the characteristics of compact structure, simple operation, reasonable layout, and easy maintenance.

Each type of unit is mainly based on land-based origin. The frequency can be divided into 50HZ and 60HZ. It can be operated by a single unit or multiple units.

2. Technical characteristics

The gas mixing device uses a Vendry tube mixer or an electronically controlled mixer, with correct gas distribution timing and a reasonable ignition advance angle to facilitate the full combustion of combustible gas.

A reasonable air intake system makes air and gas mix more evenly, burn more fully, and improve gas utilization. Explosion-proof doors are installed at both ends of the air intake pipe.

The intake pipe is designed to reduce tar condensation in the intake pipe and has good maintainability.

Reasonably design the cam line type and select reasonable intake and exhaust timing to control the opening time and overlap angle of the intake and exhaust valves within a reasonable range, which can not only reduce the risk of intake pipe backfire, but also ensure the corresponding A certain degree of scavenging is beneficial to reducing the exhaust temperature.

The exhaust pipe adopts a water-cooling structure to reduce the temperature around the generator.

The ignition system produced by the American ALTRONIC company is used to obtain high ignition energy and ignition time, ensure the reliability of ignition, and meet the ignition needs of biomass energy.

3. Main advantages of 300 series biomass gas generating units

High power. The power of the unit can reach 550kW, which is more than twice the current high power in the domestic market, and can better meet the complete set needs of large-scale power stations.

High reliability. The prototype of this unit is a 8300 medium-speed diesel engine with mature domestic technology (maximum power 1103kW/600rpm). The power of the gas engine is relatively low, and the corresponding mechanical load is much smaller than the diesel engine specification, so the reliability is high.

Save material consumption. When the load of an 8300 biomass engine is 400kW, compared with two 200kW units when the load is (190+190)kW, it saves about 5% of materials, reduces the cost of power generation, and shows good economics.

The cylinder exhaust temperature is relatively low. Compared with the existing domestic 200kW unit, the exhaust temperature is 60~90~C lower. The thermal load of the engine is greatly reduced, the service life of valves and other components is extended, and the reliability of the entire machine is further improved.

4. Conditions of use

1) The gas composition and calorific value are as follows:

Gas composition and calorific value table

Gas composition and calorific value table

2) Air source conditions:

Biomass gas should undergo appropriate filtration, gas-liquid separation, and pressure stabilization before use. If the temperature is too high, it should be cooled and ensure that there is no liquid component in the gas. Pressure change rate ≤1kPa/min, tar content ≤20mg/Nm3, hydrogen volume content ≤15%, impurity particle size ≤5μm, moisture content ≤20mg/Nm3, impurity content ≤30mg/Nm3.

Aerial view of biomass power plant