Customized operation mode

Biogas/natural gas/oil field associated gas generator set is used to generate electricity from biogas, natural gas, and oil field associated gas. It can be operated in parallel to the grid or as a distributed energy system. Multiple units can be operated in parallel and isolated on the grid. The power distribution is even and the load response is good. Timely and stable operation.

New technology, new materials, long service life

In view of the corrosive characteristics of biogas containing sulfur, new processes and new materials were used to carry out anti-corrosion treatment on the engine intake system, combustion system components, intercoolers, superchargers and other ancillary equipment to extend their service life.

Application areas

It is suitable for piped natural gas and oil well associated gas in cities, oil fields, gas fields and other places; industrial sewage biogas, livestock manure biogas, food waste biogas, and landfill biogas.

▪ Mainly used in natural gas, biogas, oil field gas cooling, heat and power combined power distributed energy systems; ▪ Easy installation, low noise, integrated module design; ▪ Economical and high thermal efficiency; ▪ Long uptime, reliability and low maintenance costs; ▪ Modular assembly allows installation in limited space. | Air source requirements ▪ Inlet gas temperature ≤40℃ |

Application instructions:

The optimized design is based on the characteristics of high sulfur content and high CO2 content in gas. It has good stability and strong adaptability, and has great influence in the field of biogas/natural gas/oil field associated gas power generation.

50-400kW series biogas, natural gas and oil field associated gas generator sets |

400-500kW series biogas, natural gas and oil field associated gas generator sets |

1200kW series biogas natural gas oil field associated gas generator set |

Versatile applications, reliable performance

Refining and chemical production enterprises such as shale oil, blue carbon, coke, calcium carbide, and ferroalloys will produce a large amount of low calorific value industrial exhaust gas during the production process. The main components of these combustible gases are hydrogen and carbon monoxide. They have complex compositions, many impurities, unstable compositions, high toxicity, and are flammable and explosive. Except for a small number of refining and chemical plants for their own use, most of the remaining gases are burned and evacuated to waste. For this type of gas, the company has developed high-power gas generator sets suitable for various industrial exhaust gases such as coke oven gas, producer gas, blue charcoal exhaust gas, oil shale exhaust gas, calcium carbide exhaust gas, ferroalloy exhaust gas, etc. Utilizing these combustible industrial exhaust gases for power generation and turning waste into treasure not only solves the problem of air pollution caused by emissions, but also saves electricity resources.

Technical advantages of industrial exhaust gas generator sets ▪ It has strong adaptability to hydrogen and carbon monoxide gases and a wide range of adaptability;▪ Good tolerance to tar, dust, sulfur, naphthalene and other impurities in refining gas; ▪ The air is mixed with the gas cylinder, and the high hydrogen gas has no flashback problem; ▪ Automatic air-fuel ratio adjustment, strong adaptability to gas fluctuations, and stable power output; ▪ It has one-button start, automatic closing and loading functions, and has a high degree of automation; ▪ The annual running time is long, the failure rate is low, the maintenance cycle is long, and the operating cost is low. | Air source requirements ▪ Inlet gas temperature ≤40℃ |

Application instructions:

In 2012, this product passed the scientific and technological achievements appraisal organized by the Shandong Provincial Department of Science and Technology. This product has been promoted and applied in the power generation fields of coke oven gas, producer gas, blue carbon tail gas, oil shale tail gas, calcium carbide tail gas, and ferroalloy tail gas. It has achieved good economic and social benefits and has been well received by users.

300-400kW series industrial exhaust gas generator sets |

500-600kW series industrial exhaust gas generator sets |

800-1200kW series industrial exhaust gas generator sets |

Traditional CHP solutions

During coal mine production, the drainage gas pumped up from the drainage station with a methane concentration of more than 8% is used as fuel to generate electricity after simple processing. The generated power can be integrated into the coal mine's internal network or directly into the national grid. The high-temperature exhaust smoke of the engine passes through the exhaust heat recovery device, and the recovered heat energy can be used for heating, bathing, and underground hot air delivery in winter.

Technical advantages of gas generator sets ▪ Using electronically controlled mixer and closed-loop automatic control technology, the air-to-air ratio can be adjusted in real time, with strong adaptability to gas fluctuations and stable power output; ▪ It has one-button start, automatic closing and loading functions, and has a high degree of automation; ▪ The unit can operate continuously at full load, with an annual operating time of up to 7,500 hours, and high power generation income; ▪ The unit failure rate is low, the overhaul cycle is long, and the operating cost is low. | Air source requirements ▪ Inlet gas temperature ≤40℃ |

Application instructions:

The power range of gas-fired generator sets is wide, adapting to the characteristics of low gas concentration and large gas source fluctuations in coal mines. Low-concentration gas generator sets have outstanding advantages and have been widely used in major domestic coal mines.

400-500kW series gas generator set |

600-1000kW series gas generator set |

1200kW series gas generator set |

Reliable Performance, Realized Benefits

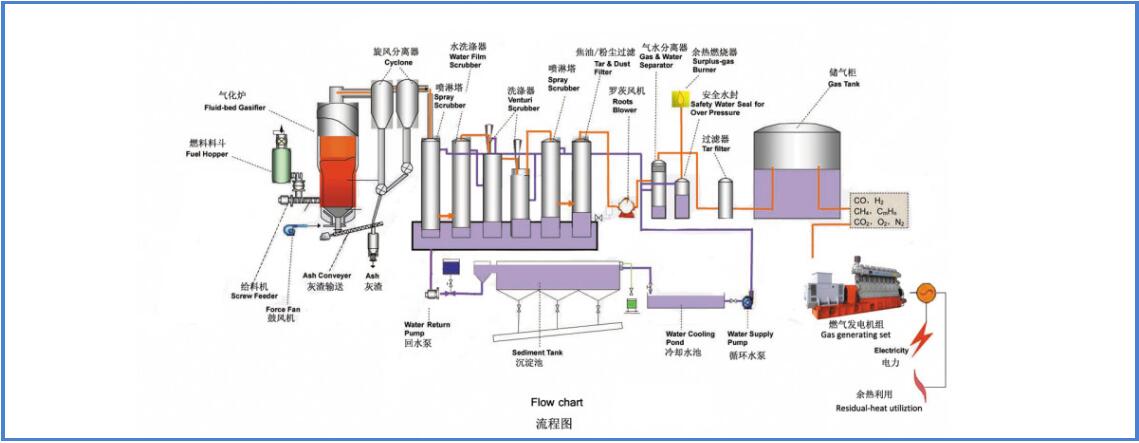

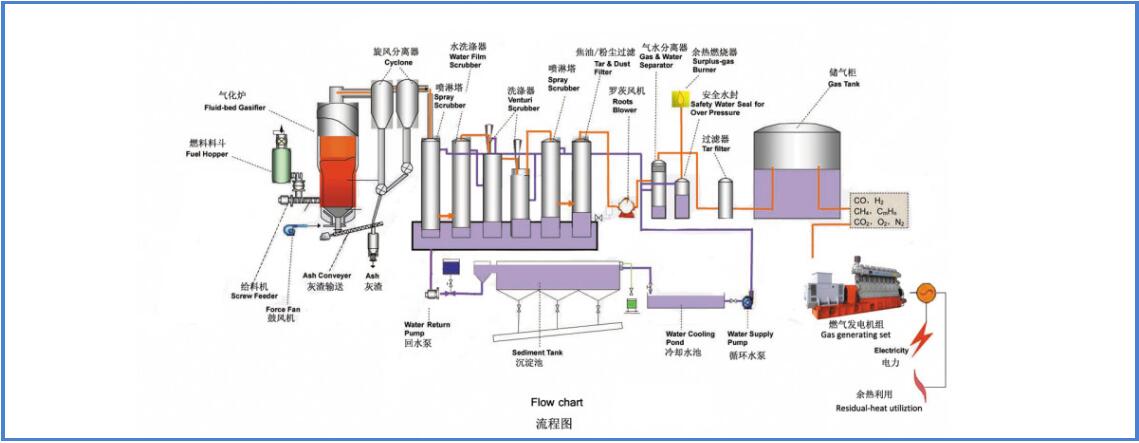

Understory waste and branches in forest areas; agricultural straw and cotton stalks; rice husks from farms; bagasse from sugar mills; sawdust from wood processing plants; municipal domestic waste, etc., are processed through corresponding biomass gasification devices to reduce the amount of waste. The combustible gas produced by oxygen combustion, whose main component is carbon monoxide, can generate electricity after corresponding purification. It uses renewable energy and protects the environment. It is also a project encouraged by national policies.

Biomass/waste gasification power generation process flow

Various applications

Forest waste and branches in forest areas; agricultural straw and cotton stalks; rice husks from farms; bagasse from sugar mills; sawdust from wood processing plants; urban domestic waste, etc.

| Technical advantages ▪ Non-supercharged naturally aspirated, double-layer tube air intake system, high tolerance to tar; ▪ The intake valve box is removable for easy maintenance; ▪ External mixing or internal mixing intake system can be selected according to the hydrogen content; ▪ Adapt to low calorific value biomass gas and high hydrogen content; ▪ High degree of automation, high safety and low operating cost; | Air source requirements ▪ Inlet gas temperature ≤40℃ ▪ Gas pressure 2.5~10kPa ▪ Pressure change rate ≤1kPa/min ▪ Gas calorific value ≥ 4.0MJ/Nm³; moisture content ≤ 40g/Nm³, excluding free water ▪ Dust content ≤30mg/Nm³ ▪ Dust particle size≤5μm ▪ Tar content ≤50mg/Nm³; ▪ Hydrogen sulfide content ≤50mg/Nm³; ▪ Total sulfur content≤100mg/Nm³ ▪ Ammonia content ≤20mg/Nm³ ▪ Chlorine content ≤50mg/Nm³ ▪ Hydrogen volume content ≤50% ▪ Oxygen volume content ≤1% |

Application instructions:

The biomass gas generator set adopts non-supercharged naturally aspirated air intake technology. The reliability and continuous operation performance of the unit are unmatched by domestic counterparts. It has market advantages and is used in Japan, South Korea, Thailand, Indonesia, Croatia, Romania, Lithuania, etc. Widely used in the country.

1MW biomass power station 1MW biomass power station |  350kW Municipal Waste Generator Set 350kW Municipal Waste Generator Set |  100kW series biomass gas waste gas generator set 100kW series biomass gas waste gas generator set |

Zichai New Energy is affiliated to China Agricultural Development (Group) Co., Ltd. and is a high-tech enterprise. As China's core production base for large engines and key components, China's core innovation base for new energy utilization equipment manufacturing and technical services, it has 50 years of experience in internal combustion engines. R&D and manufacturing foundation, 20 years of experience in gas power generation engineering application, annual production capacity of 10,000 sets of internal combustion power equipment, and a sound R&D, manufacturing, sales, and service system, leading the development of China's internal combustion power field.

Customized operation mode

Biogas/natural gas/oil field associated gas generator set is used to generate electricity from biogas, natural gas, and oil field associated gas. It can be operated in parallel to the grid or as a distributed energy system. Multiple units can be operated in parallel and isolated on the grid. The power distribution is even and the load response is good. Timely and stable operation.

New technology, new materials, long service life

In view of the corrosive characteristics of biogas containing sulfur, new processes and new materials were used to carry out anti-corrosion treatment on the engine intake system, combustion system components, intercoolers, superchargers and other ancillary equipment to extend their service life.

Application areas

It is suitable for piped natural gas and oil well associated gas in cities, oil fields, gas fields and other places; industrial sewage biogas, livestock manure biogas, food waste biogas, and landfill biogas.

▪ Mainly used in natural gas, biogas, oil field gas cooling, heat and power combined power distributed energy systems; ▪ Easy installation, low noise, integrated module design; ▪ Economical and high thermal efficiency; ▪ Long uptime, reliability and low maintenance costs; ▪ Modular assembly allows installation in limited space. | Air source requirements ▪ Inlet gas temperature ≤40℃ |

Application instructions:

The optimized design is based on the characteristics of high sulfur content and high CO2 content in gas. It has good stability and strong adaptability, and has great influence in the field of biogas/natural gas/oil field associated gas power generation.

50-400kW series biogas, natural gas and oil field associated gas generator sets |

400-500kW series biogas, natural gas and oil field associated gas generator sets |

1200kW series biogas natural gas oil field associated gas generator set |

Versatile applications, reliable performance

Refining and chemical production enterprises such as shale oil, blue carbon, coke, calcium carbide, and ferroalloys will produce a large amount of low calorific value industrial exhaust gas during the production process. The main components of these combustible gases are hydrogen and carbon monoxide. They have complex compositions, many impurities, unstable compositions, high toxicity, and are flammable and explosive. Except for a small number of refining and chemical plants for their own use, most of the remaining gases are burned and evacuated to waste. For this type of gas, the company has developed high-power gas generator sets suitable for various industrial exhaust gases such as coke oven gas, producer gas, blue charcoal exhaust gas, oil shale exhaust gas, calcium carbide exhaust gas, ferroalloy exhaust gas, etc. Utilizing these combustible industrial exhaust gases for power generation and turning waste into treasure not only solves the problem of air pollution caused by emissions, but also saves electricity resources.

Technical advantages of industrial exhaust gas generator sets ▪ It has strong adaptability to hydrogen and carbon monoxide gases and a wide range of adaptability;▪ Good tolerance to tar, dust, sulfur, naphthalene and other impurities in refining gas; ▪ The air is mixed with the gas cylinder, and the high hydrogen gas has no flashback problem; ▪ Automatic air-fuel ratio adjustment, strong adaptability to gas fluctuations, and stable power output; ▪ It has one-button start, automatic closing and loading functions, and has a high degree of automation; ▪ The annual running time is long, the failure rate is low, the maintenance cycle is long, and the operating cost is low. | Air source requirements ▪ Inlet gas temperature ≤40℃ |

Application instructions:

In 2012, this product passed the scientific and technological achievements appraisal organized by the Shandong Provincial Department of Science and Technology. This product has been promoted and applied in the power generation fields of coke oven gas, producer gas, blue carbon tail gas, oil shale tail gas, calcium carbide tail gas, and ferroalloy tail gas. It has achieved good economic and social benefits and has been well received by users.

300-400kW series industrial exhaust gas generator sets |

500-600kW series industrial exhaust gas generator sets |

800-1200kW series industrial exhaust gas generator sets |

Traditional CHP solutions

During coal mine production, the drainage gas pumped up from the drainage station with a methane concentration of more than 8% is used as fuel to generate electricity after simple processing. The generated power can be integrated into the coal mine's internal network or directly into the national grid. The high-temperature exhaust smoke of the engine passes through the exhaust heat recovery device, and the recovered heat energy can be used for heating, bathing, and underground hot air delivery in winter.

Technical advantages of gas generator sets ▪ Using electronically controlled mixer and closed-loop automatic control technology, the air-to-air ratio can be adjusted in real time, with strong adaptability to gas fluctuations and stable power output; ▪ It has one-button start, automatic closing and loading functions, and has a high degree of automation; ▪ The unit can operate continuously at full load, with an annual operating time of up to 7,500 hours, and high power generation income; ▪ The unit failure rate is low, the overhaul cycle is long, and the operating cost is low. | Air source requirements ▪ Inlet gas temperature ≤40℃ |

Application instructions:

The power range of gas-fired generator sets is wide, adapting to the characteristics of low gas concentration and large gas source fluctuations in coal mines. Low-concentration gas generator sets have outstanding advantages and have been widely used in major domestic coal mines.

400-500kW series gas generator set |

600-1000kW series gas generator set |

1200kW series gas generator set |

Reliable Performance, Realized Benefits

Understory waste and branches in forest areas; agricultural straw and cotton stalks; rice husks from farms; bagasse from sugar mills; sawdust from wood processing plants; municipal domestic waste, etc., are processed through corresponding biomass gasification devices to reduce the amount of waste. The combustible gas produced by oxygen combustion, whose main component is carbon monoxide, can generate electricity after corresponding purification. It uses renewable energy and protects the environment. It is also a project encouraged by national policies.

Biomass/waste gasification power generation process flow

Various applications

Forest waste and branches in forest areas; agricultural straw and cotton stalks; rice husks from farms; bagasse from sugar mills; sawdust from wood processing plants; urban domestic waste, etc.

| Technical advantages ▪ Non-supercharged naturally aspirated, double-layer tube air intake system, high tolerance to tar; ▪ The intake valve box is removable for easy maintenance; ▪ External mixing or internal mixing intake system can be selected according to the hydrogen content; ▪ Adapt to low calorific value biomass gas and high hydrogen content; ▪ High degree of automation, high safety and low operating cost; | Air source requirements ▪ Inlet gas temperature ≤40℃ ▪ Gas pressure 2.5~10kPa ▪ Pressure change rate ≤1kPa/min ▪ Gas calorific value ≥ 4.0MJ/Nm³; moisture content ≤ 40g/Nm³, excluding free water ▪ Dust content ≤30mg/Nm³ ▪ Dust particle size≤5μm ▪ Tar content ≤50mg/Nm³; ▪ Hydrogen sulfide content ≤50mg/Nm³; ▪ Total sulfur content≤100mg/Nm³ ▪ Ammonia content ≤20mg/Nm³ ▪ Chlorine content ≤50mg/Nm³ ▪ Hydrogen volume content ≤50% ▪ Oxygen volume content ≤1% |

Application instructions:

The biomass gas generator set adopts non-supercharged naturally aspirated air intake technology. The reliability and continuous operation performance of the unit are unmatched by domestic counterparts. It has market advantages and is used in Japan, South Korea, Thailand, Indonesia, Croatia, Romania, Lithuania, etc. Widely used in the country.

1MW biomass power station 1MW biomass power station |  350kW Municipal Waste Generator Set 350kW Municipal Waste Generator Set |  100kW series biomass gas waste gas generator set 100kW series biomass gas waste gas generator set |

Zichai New Energy is affiliated to China Agricultural Development (Group) Co., Ltd. and is a high-tech enterprise. As China's core production base for large engines and key components, China's core innovation base for new energy utilization equipment manufacturing and technical services, it has 50 years of experience in internal combustion engines. R&D and manufacturing foundation, 20 years of experience in gas power generation engineering application, annual production capacity of 10,000 sets of internal combustion power equipment, and a sound R&D, manufacturing, sales, and service system, leading the development of China's internal combustion power field.