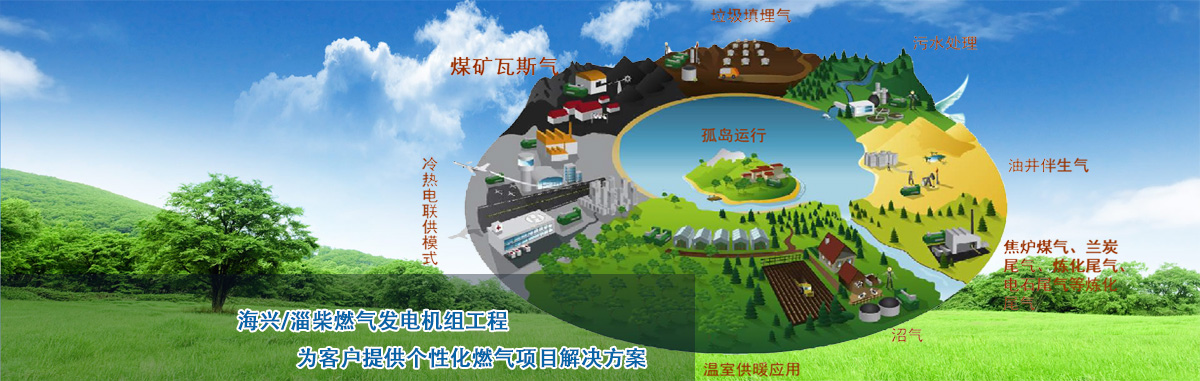

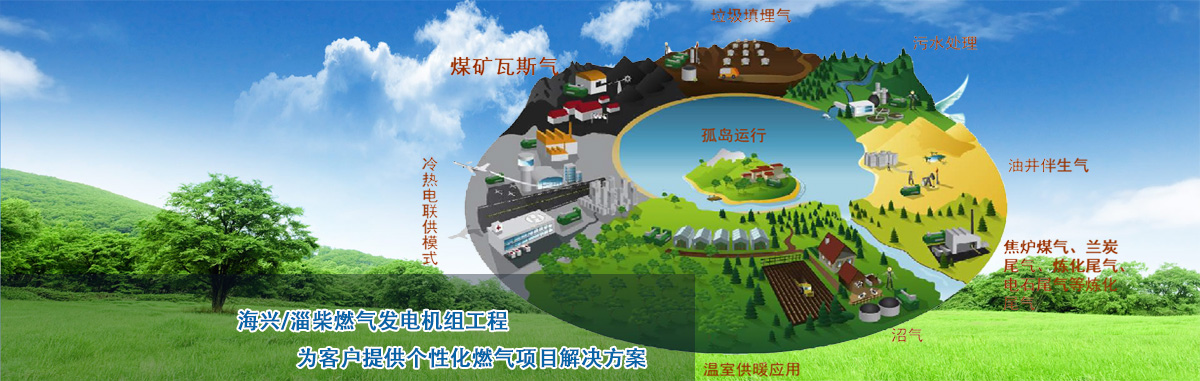

Comprehensive utilization of industrial gas

Zichai 300 series gas generator set

Application areas

It is suitable for piped natural gas and oil well associated gas in cities, oil fields, gas fields and other places; industrial sewage biogas, livestock manure biogas, food waste biogas, and landfill biogas.

| Technical advantages and characteristics of Zichai 300 gas generator set 1) Low speed: ensure the service life of the unit; 2) Easy maintenance: The in-line upright structure simplifies the engine layout, has a simple structure and is easy to maintain; the detachable intake valve box allows maintenance of the intake valve and cleaning of tar without removing the cylinder head; 3) Can output high, medium and low voltages: reducing initial investment and operating costs; 4) Wide adaptability to gas: especially available gas with low calorific value and high H2 content; 5) Computer monitoring and management system: realizes intelligent management, remote monitoring and operation of the unit; 6) Calibrated power output, the annual operating time can reach more than 7500h, the overhaul cycle is about 60000h, and the service life can reach 20 years. | Speed: mainly 500r/min, 600r/min and 750r/min; Output voltage: 400V, 6300V, 10500V; Power range: 300~1200kW. |

300 series gas generator set | 300 series gas generator set | 300 series gas generator set |

300 series gas generator set | 8300 series gas generator set | 9300 series gas generator set |

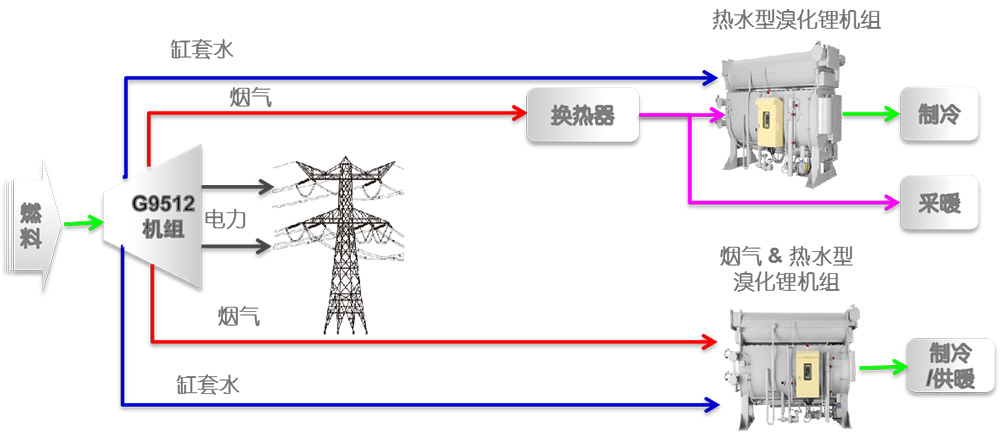

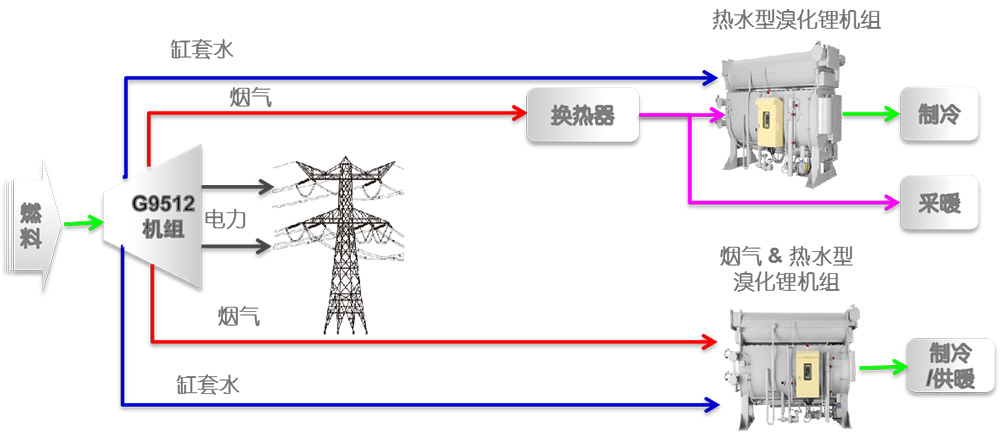

Micro energy network

G9512 series gas generator set

Application areas:Comprehensive utilization of distributed energy and urban peaking power station.

Application mode:Electric energy, cooling load, heating load (steam, hot water) are jointly supplied and matched flexibly.

| Technical equipment: Optional technical equipment: Z170, 300 series gas generator sets; Ancillary equipment: lithium bromide unit, waste heat recovery device, etc.; G9512 gas generator set is mainly used for natural gas and biogas power generation as well as cold and heating micro energy grid systems. | Advantages of G9512 series gas generator set 1) The micro-energy grid power system jointly built by Germany's LIEBHERR and Zichai; 2) Excellent electrical efficiency, which can reach more than 42%, and with comprehensive utilization, the efficiency can reach more than 87%; 3) Low investment, high energy density; 4) Automation and quick startup to ensure system stability; 5) Highly integrated, fast and convenient installation; 6) Able to maintain stable output and high efficiency in high-altitude environments; 7) Low emission, in line with German TA-luft and EU CLRAP pollutant restriction regulations; 8) Start overhaul after 60,000 hours of operation. |

G9512 series gas generator set |

G9512 series gas generator set |

Micro energy network system composed of G9512 gas generator set

Biomass molding

Raw material requirements:The chopped length of raw materials is less than 50mm, and the moisture content is 14%-25%.

Equipment composition:Molding host machine, loading conveyor, discharging conveyor, and electronic control system.

| Processing scope: Corn straw, wheat straw, alfalfa, bean straw, peanut straw (shell) and other plant straw; As well as mushroom residue, bark, sawdust, cow dung, domestic garbage and other waste. | Usage of molding fuel: Can be widely used in animal compressed feed; Fuels for residential cooking, district heating, and power generation; Biogas fermentation raw materials; Biomass gasification raw materials, etc. |

Matter Shaping Machine

Comprehensive utilization of industrial gas

Zichai 300 series gas generator set

Application areas

It is suitable for piped natural gas and oil well associated gas in cities, oil fields, gas fields and other places; industrial sewage biogas, livestock manure biogas, food waste biogas, and landfill biogas.

| Technical advantages and characteristics of Zichai 300 gas generator set 1) Low speed: ensure the service life of the unit; 2) Easy maintenance: The in-line upright structure simplifies the engine layout, has a simple structure and is easy to maintain; the detachable intake valve box allows maintenance of the intake valve and cleaning of tar without removing the cylinder head; 3) Can output high, medium and low voltages: reducing initial investment and operating costs; 4) Wide adaptability to gas: especially available gas with low calorific value and high H2 content; 5) Computer monitoring and management system: realizes intelligent management, remote monitoring and operation of the unit; 6) Calibrated power output, the annual operating time can reach more than 7500h, the overhaul cycle is about 60000h, and the service life can reach 20 years. | Speed: mainly 500r/min, 600r/min and 750r/min; Output voltage: 400V, 6300V, 10500V; Power range: 300~1200kW. |

300 series gas generator set | 300 series gas generator set | 300 series gas generator set |

300 series gas generator set | 8300 series gas generator set | 9300 series gas generator set |

Micro energy network

G9512 series gas generator set

Application areas:Comprehensive utilization of distributed energy and urban peaking power station.

Application mode:Electric energy, cooling load, heating load (steam, hot water) are jointly supplied and matched flexibly.

| Technical equipment: Optional technical equipment: Z170, 300 series gas generator sets; Ancillary equipment: lithium bromide unit, waste heat recovery device, etc.; G9512 gas generator set is mainly used for natural gas and biogas power generation as well as cold and heating micro energy grid systems. | Advantages of G9512 series gas generator set 1) The micro-energy grid power system jointly built by Germany's LIEBHERR and Zichai; 2) Excellent electrical efficiency, which can reach more than 42%, and with comprehensive utilization, the efficiency can reach more than 87%; 3) Low investment, high energy density; 4) Automation and quick startup to ensure system stability; 5) Highly integrated, fast and convenient installation; 6) Able to maintain stable output and high efficiency in high-altitude environments; 7) Low emission, in line with German TA-luft and EU CLRAP pollutant restriction regulations; 8) Start overhaul after 60,000 hours of operation. |

G9512 series gas generator set |

G9512 series gas generator set |

Micro energy network system composed of G9512 gas generator set

Biomass molding

Raw material requirements:The chopped length of raw materials is less than 50mm, and the moisture content is 14%-25%.

Equipment composition:Molding host machine, loading conveyor, discharging conveyor, and electronic control system.

| Processing scope: Corn straw, wheat straw, alfalfa, bean straw, peanut straw (shell) and other plant straw; As well as mushroom residue, bark, sawdust, cow dung, domestic garbage and other waste. | Usage of molding fuel: Can be widely used in animal compressed feed; Fuels for residential cooking, district heating, and power generation; Biogas fermentation raw materials; Biomass gasification raw materials, etc. |

Matter Shaping Machine