Low concentration gas:

Low-concentration gas is gas with a methane concentration between 8% and 30%. The amount of coal mine gas extracted is huge, at least 2/3 of which is low-concentration coal mine gas with a methane concentration below 30%. If not utilized, a large amount of energy will be wasted.

The explosion range of gas under normal temperature and pressure is 5%-16%; gas engines use the energy generated by gas combustion to drive generators to generate electricity.

There is an explosion risk in low-concentration gas transportation. In order to solve this problem, our company has designed and developed a low-concentration gas transportation guarantee system.

Low concentration gas delivery system:

Function: Transport low-concentration gas from the gas transmission end to the gas consumption end, and ensure the quality of the transported gas; the gas transmission end involved is the gas extraction station, and the gas consumption end involved is the low-concentration gas generator set.

Installation: Directly connected to the tee pipe at the exhaust port of the gas extraction station, no need for pipeline modification.

System introduction:

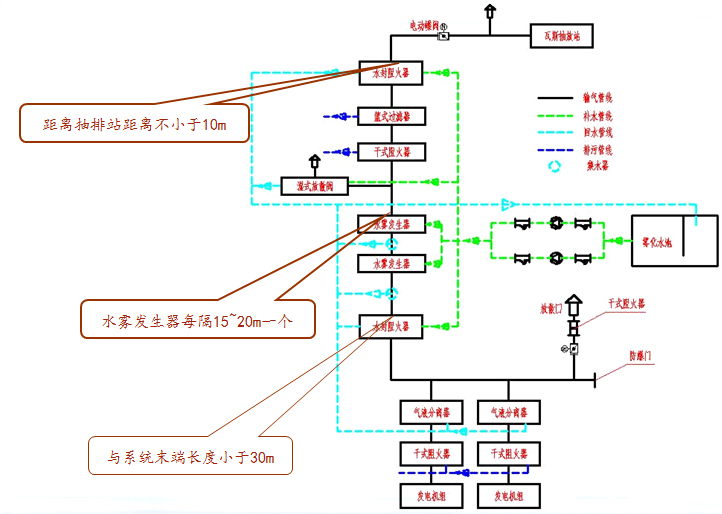

The low-concentration gas transportation guarantee system connects the gas transmission end and the gas consumption end. Multiple safeguard measures are taken throughout the entire process, including three main measures: fire prevention, explosion prevention, and explosion propagation suppression, which are implemented by single-piece water-sealed fire-blocking and explosion-proof devices, water mist generators, flame arresters and other equipment. In addition, there are multi-level auxiliary systems such as filters, gas-liquid separators, lightning rods, grounding systems, and relief systems. The main function is to reduce the risk of low-concentration gas transportation and prevent pipeline explosions from spreading to the gas transmission end and the gas consumption end. At the same time, filters and gas-liquid separators ensure that low-concentration gas meets the requirements of the gas consumer. Grounding and lightning rods help the pipeline avoid dangers such as lightning strikes and sparks. While fully guaranteeing the transportation, the quality of gas usage is ensured.

The low-concentration gas transportation support system mainly includes electric relief valves, water-sealed flame arresters, wet relief valves, dry flame arresters, basket filters, water mist generators, gas-liquid separators, valves, pressure gauges, temperature gauges, Auxiliary equipment such as water pumps and pools.

System process flow chart

Introduction to the main equipment functions of the system:

dry flame arrester: Using the principle of flame quenching in slits, stainless steel plates are bent and overlapped to form a flame-extinguishing layer with a small gap. When there is a flame in the pipeline, it will be blocked by the dry flame arrester to extinguish the flame or reduce the intensity of the fire. It acts as a hindrance to the spread of flames.

basket strainer: It mainly uses the mechanism of interception and collision to filter impurities such as particles, water vapor and dust in the transported gas. It prevents impurities from clogging the dry flame arrester and extends the service life of the dry flame arrester and pipeline valves.

Wet relief valve: Adjust the pressure of the control pipeline through changes in water level, release the over-pressure in the transportation pipeline, and protect the safety of transportation equipment and pipelines.

fine water mist generator: Utilizes the effects of cooling and dilution to reduce the temperature and concentration of gas in the delivery pipeline and inhibit the occurrence of combustion.

water seal flame arrester: The liquid level is controlled through the internal overflow device to adjust the pipeline pressure, which not only ensures that the gas can flow smoothly in the transportation pipeline, but also achieves the fire-retardant function, and also plays the role of suppressing the spread of explosions. .

Gas-liquid separator: It has multiple functions such as dehydration, dust removal, and voltage stabilization. It is a gas purification and treatment equipment.

Low concentration gas:

Low-concentration gas is gas with a methane concentration between 8% and 30%. The amount of coal mine gas extracted is huge, at least 2/3 of which is low-concentration coal mine gas with a methane concentration below 30%. If not utilized, a large amount of energy will be wasted.

The explosion range of gas under normal temperature and pressure is 5%-16%; gas engines use the energy generated by gas combustion to drive generators to generate electricity.

There is an explosion risk in low-concentration gas transportation. In order to solve this problem, our company has designed and developed a low-concentration gas transportation guarantee system.

Low concentration gas delivery system:

Function: Transport low-concentration gas from the gas transmission end to the gas consumption end, and ensure the quality of the transported gas; the gas transmission end involved is the gas extraction station, and the gas consumption end involved is the low-concentration gas generator set.

Installation: Directly connected to the tee pipe at the exhaust port of the gas extraction station, no need for pipeline modification.

System introduction:

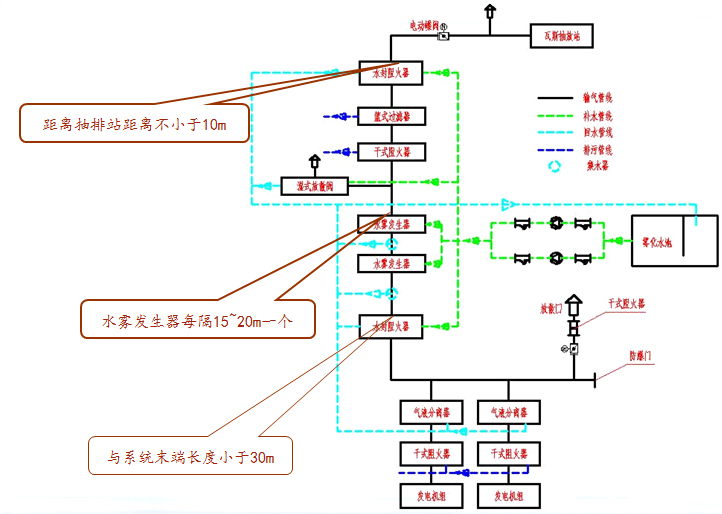

The low-concentration gas transportation guarantee system connects the gas transmission end and the gas consumption end. Multiple safeguard measures are taken throughout the entire process, including three main measures: fire prevention, explosion prevention, and explosion propagation suppression, which are implemented by single-piece water-sealed fire-blocking and explosion-proof devices, water mist generators, flame arresters and other equipment. In addition, there are multi-level auxiliary systems such as filters, gas-liquid separators, lightning rods, grounding systems, and relief systems. The main function is to reduce the risk of low-concentration gas transportation and prevent pipeline explosions from spreading to the gas transmission end and the gas consumption end. At the same time, filters and gas-liquid separators ensure that low-concentration gas meets the requirements of the gas consumer. Grounding and lightning rods help the pipeline avoid dangers such as lightning strikes and sparks. While fully guaranteeing the transportation, the quality of gas usage is ensured.

The low-concentration gas transportation support system mainly includes electric relief valves, water-sealed flame arresters, wet relief valves, dry flame arresters, basket filters, water mist generators, gas-liquid separators, valves, pressure gauges, temperature gauges, Auxiliary equipment such as water pumps and pools.

System process flow chart

Introduction to the main equipment functions of the system:

dry flame arrester: Using the principle of flame quenching in slits, stainless steel plates are bent and overlapped to form a flame-extinguishing layer with a small gap. When there is a flame in the pipeline, it will be blocked by the dry flame arrester to extinguish the flame or reduce the intensity of the fire. It acts as a hindrance to the spread of flames.

basket strainer: It mainly uses the mechanism of interception and collision to filter impurities such as particles, water vapor and dust in the transported gas. It prevents impurities from clogging the dry flame arrester and extends the service life of the dry flame arrester and pipeline valves.

Wet relief valve: Adjust the pressure of the control pipeline through changes in water level, release the over-pressure in the transportation pipeline, and protect the safety of transportation equipment and pipelines.

fine water mist generator: Utilizes the effects of cooling and dilution to reduce the temperature and concentration of gas in the delivery pipeline and inhibit the occurrence of combustion.

water seal flame arrester: The liquid level is controlled through the internal overflow device to adjust the pipeline pressure, which not only ensures that the gas can flow smoothly in the transportation pipeline, but also achieves the fire-retardant function, and also plays the role of suppressing the spread of explosions. .

Gas-liquid separator: It has multiple functions such as dehydration, dust removal, and voltage stabilization. It is a gas purification and treatment equipment.