The Holset exhaust gas turbocharger can ensure more adequate air intake, improve engine efficiency, further improve combustion, and reduce engine specific fuel consumption.

Air-to-intercooling technology ensures more adequate air intake and better fuel economy.

• Compact structure and easy maintenance

Replaceable wet cylinder liner has good heat dissipation effect and is easy to replace.

The parts of all models are highly versatile, highly serialized and easy to maintain.

Both the cylinder block and the cylinder head adopt built-in pressure lubricating oil passages, which have compact structure and low failure rate.

• Advanced design and reliable performance

Cylinder body: Made of high-strength alloy cast iron, with good rigidity, low vibration and low noise.

Cylinder head: Four-valve design per cylinder, optimized air/fuel mixture ratio, combustion and emissions; one cover per cylinder, easy maintenance.

Camshaft: The dual camshaft design can control valve and injection timing, and the optimized cam profile can reduce impact force and improve reliability and durability.

Crankshaft: An integral crankshaft made of high-strength forged steel. The induction quenching process of fillets and journals can ensure higher fatigue strength of the crankshaft.

Piston: Using aluminum alloy casting technology, the ω-shaped head and barrel-shaped skirt design can compensate for thermal expansion and contraction to ensure good fit.

Lubrication system: All moving parts are forced lubrication; a large-capacity gear pump provides pressure lubricating oil to lubricate the bearings and cool the pistons; the oil cooler, full-flow filter, and bypass filter maintain good oil condition.

Fuel system: Cummins' patented PT fuel system optimizes combustion and provides surging power; the STC distributed timing system ensures good combustion in all working conditions; it adopts a low-pressure fuel supply system and is equipped with a one-way fuel circuit, which is reliable.

Cooling system: forced water cooling by gear centrifugal water pump, large flow water channel design, good cooling effect; spin-on water filter and DCA additive can prevent rust and cavitation, control coolant acidity and remove impurities.

Intake and exhaust system: Holset exhaust gas supercharger further improves combustion; pressure-type pulse exhaust pipe can make full use of exhaust gas energy and improve engine efficiency; air-to-air intercooling technology ensures fuel economy and good emissions.

• Mature products, famous all over the world

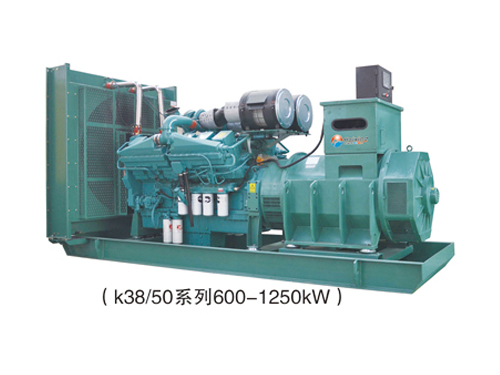

Wide range of applications: Since Cummins entered China in 1975, the K38 series engines have been widely used in engineering machinery, heavy-duty vehicles, power generation, ship power and other fields; it has formed strategic partners with important customers.

High reputation: As one of the main models of the Cummins family, the K38 series engines have won high recognition from customers in various fields for their power, ultra-low fuel consumption, high reliability and low maintenance costs.

Technology upgrade: Air-to-air intercooling, slow starting and other technologies have further improved the engine's reliability, power, fuel economy and emissions. The QSK38 engine launched in 2008 uses electronic injection technology with a power of 806-1200kW, which can meet the third stage emission standards of non-road mobile machinery.