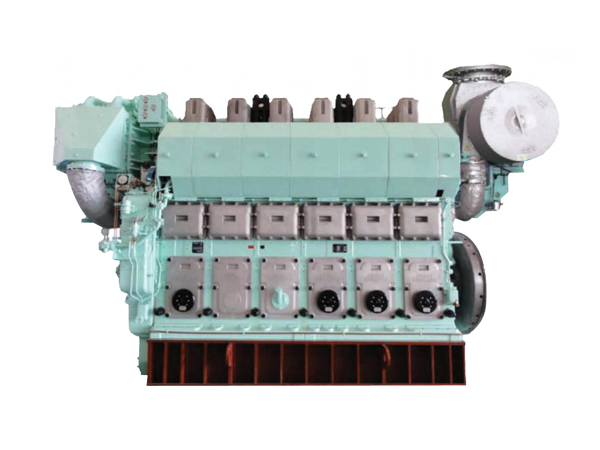

Zichai N350/S dual-fuel engine is a medium-speed inline four-stroke high-power LNG/diesel dual-fuel engine. With the increasingly stringent emission regulations and the increasing shortage of petroleum energy, energy saving and low carbon have become the leading directions for the development of internal combustion engine technology. Liquefaction Natural gas (LNG) has the characteristics of high energy density and low emissions (which can effectively reduce NOx emissions). It is of great practical significance in promoting my country's industrial transformation and upgrading and the adjustment of the national energy structure.

Based on the N350 diesel engine, the N350/S dual-fuel engine adds a natural gas intake system and control system, which mainly include natural gas intake pipes, electronic control units (ECUs), sensors, etc. ·The N350/S dual-fuel engine does not change the various systems of the N350 diesel engine and has high reliability.

The control logic of the N350/S dual-fuel engine mainly includes natural gas injection control, load control, speed control, security control, etc. The N350/S dual-fuel engine forms a comprehensive engine coverage through control program design and data collection from crankshaft speed sensor, cam speed sensor, oil pressure, fuel temperature, charge air temperature, gas temperature, gas pressure, governor actuator throttle position, etc. The MAP chart of all working conditions enables free switching between dual-fuel mode and fuel mode and stable operation of the dual-fuel engine.

From the gas inlet pipe to the gas injection valve, a double-wall pipe structure is used. ·Using reasonable control logic, automatic conversion of dual-fuel engine modes can be realized, ensuring full-load operation in pure diesel mode when there is a lack of gas. The explosion-proof door is installed on the intercooler rear nozzle, facing the pressurized air pressure stabilizing chamber. It can quickly release the energy of gas backfire and deflagration, thereby protecting the engine intake system from damage.

6N350ZLC/S series dual-fuel engine technical specifications parameter table

| Serial numberNo | name Name | UnitUnit | Technical specifications Technical specifications | |||||

| 1 | Type Type | / | In-line, four-stroke, direct injection, turbocharged, irreversible In-line, four strokes, direct injection, turbocharger, irreversible | |||||

| 2 | model Model | / | 6N350ZLC/S-3 | 6N350ZLC/S-4 | 6N350ZLC/S-5 | 6N350ZLC/S-6 | 6N350ZLC/S-7 | 6N350ZLC/S-8 |

| 3 | Continuous power Rated power | kW/PS | 3032/4125 | 2942/4000 | 2756/3750 | 2574/3500 | 2426/3300 | 2207/3000 |

| 4 | Continuous speed Rated speed | r/min | 600 | |||||

| 5 | Cylinder diameter Cylinder bore | mm | 350 | |||||

| 6 | Piston stroke Piston stroke | mm | 450 | |||||

| 7 | Compression ratio Compression ratio | / | 6 | |||||

| 8 | Number of cylinders No. of cylinders | / | 259.77 | |||||

| 9 | total displacement Total displacement | L | 14 | |||||

| 10 | Stable working speed Minimum stable speed | r/min | 240 | |||||

| 11 | average piston speed Mean piston speed | m/s | 9 | |||||

| 12 | mean effective pressure Mean effective pressure | MPa | 2.3344 | 2.2651 | 2.1219 | 1.98 | 1.8678 | 1.6992 |

| 13 | boost pressure Supercharging pressure | MPa | 0.43±0.01 | 0.42±0.01 | 0.40±0.01 | 0.38±0.01 | 0.36±0.01 | 0.34±0.01 |

| 14 | explosive pressure Maximum explosion pressure | MPa | ≤ 17.0 | |||||

| 15 | Exhaust temperature of each cylinder Each cylinder exhaust temperature | ℃ | ≤450 | |||||

| 16 | Turbine front exhaust temperature Exhaust temperature before turbocharger | ℃ | ≤600 | |||||

| 17 | fuel consumption rate Fuel oil consumption | g/kw. h | 190+5% | |||||

| 18 | Oil consumption rate Lubrication oil consumption | g/kw. h | 1.0 | |||||

| 19 | Crank arrangement Crank arrangement | / | 1.6 2.5 3.4 | |||||

| 20 | Fire order Fire order | / | 1-2-4-6-5-3 | |||||

| 21 | Starting mode Starting method | / | Compressed air start Compressed air starting motor | |||||

| 22 | Fuel supply timing Fuel injection timing | ℃ A | 10 ~ 13.5 before top dead center | |||||

| 23 | Starting air pressureStarting air pressure | MPa | Starting pressure Max. starting pressure:2.94MPa, starting pressure Min. starting air:1.1MPa | |||||

| 24 | natural gas working pressure | MPa | 0.51 | 0.5 | 0.48 | 0.46 | 0.44 | 0.42 |

| 25 | replacement rate Maximum substitution rate | % | 90 | |||||

| 26 | Overall dimensions Dimensions(L×W×H) | mm | 5598.7×1848.5×3624 | |||||

| 27 | Piston lifting height The lifting height of piston | mm | 3323 | |||||

| 28 | Cylinder liner lifting height The lifting height of cylinder liner | mm | 3798 | |||||

| 29 | Overall machine quality Weight | kg | AboutAbout 37500 | |||||

8N350ZLC/S series dual-fuel engine technical specifications parameter table

| Serial numberNo | name Name | UnitUnit | Technical specifications Technical specifications | |||||

| 1 | Type Type | / | In-line, four-stroke, direct injection, turbocharged, irreversible In-line, four strokes, direct injection, turbocharger, irreversible | |||||

| 2 | model Model | / | 8N350ZLC/S-4 | 8N350ZLC/S-5 | 8N350ZLC/S-6 | 8N350ZLC/S-7 | 8N350ZLC/S-8 | 8N350ZLC/S-9 |

| 3 | Continuous power Rated power | kW/PS | 4043/5500 | 3822/5200 | 3675/5000 | 3455/4700 | 3310/4500 | 2942/4000 |

| 4 | Continuous speed Rated speed | r/min | 600 | |||||

| 5 | Cylinder diameter Cylinder bore | mm | 350 | |||||

| 6 | Piston stroke Piston stroke | mm | 450 | |||||

| 7 | Compression ratio Compression ratio | / | 6 | |||||

| 8 | Number of cylinders No. of cylinders | / | 346.36 | |||||

| 9 | total displacement Total displacement | L | 14 | |||||

| 10 | Stable working speed Minimum stable speed | r/min | 240 | |||||

| 11 | average piston speed Mean piston speed | m/s | 9 | |||||

| 12 | mean effective pressure Mean effective pressure | MPa | 2.3344 | 2.2651 | 2.1219 | 1.98 | 1.8678 | 1.6992 |

| 13 | boost pressure Supercharging pressure | MPa | 0.43±0.01 | 0.42±0.01 | 0.40±0.01 | 0.38±0.01 | 0.36±0.01 | 0.34±0.01 |

| 14 | explosive pressure Maximum explosion pressure | MPa | ≤17.0 | |||||

| 15 | Exhaust temperature of each cylinder Each cylinder exhaust temperature | ℃ | ≤450 | |||||

| 16 | Turbine front exhaust temperature Exhaust temperature before turbocharger | ℃ | ≤600 | |||||

| 17 | fuel consumption rate Fuel oil consumption | g/kw. h | 190+5% | |||||

| 18 | Oil consumption rate Lubrication oil consumption | g/kw. h | 1.0 | |||||

| 19 | crank arrangement Crank arrangement | / | 1.8 4.5 + 3.6 2.7 | |||||

| 20 | Fire order Fire order | / | 1-4-7-6-8-5-2-3 | |||||

| 21 | Starting mode Starting method | / | Compressed air start Compressed air starting motor | |||||

| 22 | Fuel supply timing Fuel injection timing | ℃ A | 10~13.5 before top dead center | |||||

| 23 | starting air pressure Starting air pressure | MPa | Starting pressure Max. starting pressure:2.94MPa, starting pressure Min. starting air:1.1MPa | |||||

| 24 | natural gas working pressure | MPa | 0.51 | 0.5 | 0.48 | 0.46 | 0.440.42 | |

| 25 | replacement rate Maximum substitution rate | % | 90 | |||||

| 26 | Dimensions(L×W×H) | mm | 6598.7×2655×4141 | |||||

| 27 | Piston lifting height The lifting height of piston | mm | 3323 | |||||

| 28 | Cylinder liner lifting height The lifting height of cylinder liner | mm | 3798 | |||||

| 29 | Overall machine quality Weight | kg | AboutAbout 47000 | |||||

Zichai N350/S dual-fuel engine is a medium-speed inline four-stroke high-power LNG/diesel dual-fuel engine. With the increasingly stringent emission regulations and the increasing shortage of petroleum energy, energy saving and low carbon have become the leading directions for the development of internal combustion engine technology. Liquefaction Natural gas (LNG) has the characteristics of high energy density and low emissions (which can effectively reduce NOx emissions). It is of great practical significance in promoting my country's industrial transformation and upgrading and the adjustment of the national energy structure.

Based on the N350 diesel engine, the N350/S dual-fuel engine adds a natural gas intake system and control system, which mainly include natural gas intake pipes, electronic control units (ECUs), sensors, etc. ·The N350/S dual-fuel engine does not change the various systems of the N350 diesel engine and has high reliability.

The control logic of the N350/S dual-fuel engine mainly includes natural gas injection control, load control, speed control, security control, etc. The N350/S dual-fuel engine forms a comprehensive engine coverage through control program design and data collection from crankshaft speed sensor, cam speed sensor, oil pressure, fuel temperature, charge air temperature, gas temperature, gas pressure, governor actuator throttle position, etc. The MAP chart of all working conditions enables free switching between dual-fuel mode and fuel mode and stable operation of the dual-fuel engine.

From the gas inlet pipe to the gas injection valve, a double-wall pipe structure is used. ·Using reasonable control logic, automatic conversion of dual-fuel engine modes can be realized, ensuring full-load operation in pure diesel mode when there is a lack of gas. The explosion-proof door is installed on the intercooler rear nozzle, facing the pressurized air pressure stabilizing chamber. It can quickly release the energy of gas backfire and deflagration, thereby protecting the engine intake system from damage.

6N350ZLC/S series dual-fuel engine technical specifications parameter table

| Serial numberNo | name Name | UnitUnit | Technical specifications Technical specifications | |||||

| 1 | Type Type | / | In-line, four-stroke, direct injection, turbocharged, irreversible In-line, four strokes, direct injection, turbocharger, irreversible | |||||

| 2 | model Model | / | 6N350ZLC/S-3 | 6N350ZLC/S-4 | 6N350ZLC/S-5 | 6N350ZLC/S-6 | 6N350ZLC/S-7 | 6N350ZLC/S-8 |

| 3 | Continuous power Rated power | kW/PS | 3032/4125 | 2942/4000 | 2756/3750 | 2574/3500 | 2426/3300 | 2207/3000 |

| 4 | Continuous speed Rated speed | r/min | 600 | |||||

| 5 | Cylinder diameter Cylinder bore | mm | 350 | |||||

| 6 | Piston stroke Piston stroke | mm | 450 | |||||

| 7 | Compression ratio Compression ratio | / | 6 | |||||

| 8 | Number of cylinders No. of cylinders | / | 259.77 | |||||

| 9 | total displacement Total displacement | L | 14 | |||||

| 10 | Stable working speed Minimum stable speed | r/min | 240 | |||||

| 11 | average piston speed Mean piston speed | m/s | 9 | |||||

| 12 | mean effective pressure Mean effective pressure | MPa | 2.3344 | 2.2651 | 2.1219 | 1.98 | 1.8678 | 1.6992 |

| 13 | boost pressure Supercharging pressure | MPa | 0.43±0.01 | 0.42±0.01 | 0.40±0.01 | 0.38±0.01 | 0.36±0.01 | 0.34±0.01 |

| 14 | explosive pressure Maximum explosion pressure | MPa | ≤ 17.0 | |||||

| 15 | Exhaust temperature of each cylinder Each cylinder exhaust temperature | ℃ | ≤450 | |||||

| 16 | Turbine front exhaust temperature Exhaust temperature before turbocharger | ℃ | ≤600 | |||||

| 17 | fuel consumption rate Fuel oil consumption | g/kw. h | 190+5% | |||||

| 18 | Oil consumption rate Lubrication oil consumption | g/kw. h | 1.0 | |||||

| 19 | Crank arrangement Crank arrangement | / | 1.6 2.5 3.4 | |||||

| 20 | Fire order Fire order | / | 1-2-4-6-5-3 | |||||

| 21 | Starting mode Starting method | / | Compressed air start Compressed air starting motor | |||||

| 22 | Fuel supply timing Fuel injection timing | ℃ A | 10 ~ 13.5 before top dead center | |||||

| 23 | Starting air pressureStarting air pressure | MPa | Starting pressure Max. starting pressure:2.94MPa, starting pressure Min. starting air:1.1MPa | |||||

| 24 | natural gas working pressure | MPa | 0.51 | 0.5 | 0.48 | 0.46 | 0.44 | 0.42 |

| 25 | replacement rate Maximum substitution rate | % | 90 | |||||

| 26 | Overall dimensions Dimensions(L×W×H) | mm | 5598.7×1848.5×3624 | |||||

| 27 | Piston lifting height The lifting height of piston | mm | 3323 | |||||

| 28 | Cylinder liner lifting height The lifting height of cylinder liner | mm | 3798 | |||||

| 29 | Overall machine quality Weight | kg | AboutAbout 37500 | |||||

8N350ZLC/S series dual-fuel engine technical specifications parameter table

| Serial numberNo | name Name | UnitUnit | Technical specifications Technical specifications | |||||

| 1 | Type Type | / | In-line, four-stroke, direct injection, turbocharged, irreversible In-line, four strokes, direct injection, turbocharger, irreversible | |||||

| 2 | model Model | / | 8N350ZLC/S-4 | 8N350ZLC/S-5 | 8N350ZLC/S-6 | 8N350ZLC/S-7 | 8N350ZLC/S-8 | 8N350ZLC/S-9 |

| 3 | Continuous power Rated power | kW/PS | 4043/5500 | 3822/5200 | 3675/5000 | 3455/4700 | 3310/4500 | 2942/4000 |

| 4 | Continuous speed Rated speed | r/min | 600 | |||||

| 5 | Cylinder diameter Cylinder bore | mm | 350 | |||||

| 6 | Piston stroke Piston stroke | mm | 450 | |||||

| 7 | Compression ratio Compression ratio | / | 6 | |||||

| 8 | Number of cylinders No. of cylinders | / | 346.36 | |||||

| 9 | total displacement Total displacement | L | 14 | |||||

| 10 | Stable working speed Minimum stable speed | r/min | 240 | |||||

| 11 | average piston speed Mean piston speed | m/s | 9 | |||||

| 12 | mean effective pressure Mean effective pressure | MPa | 2.3344 | 2.2651 | 2.1219 | 1.98 | 1.8678 | 1.6992 |

| 13 | boost pressure Supercharging pressure | MPa | 0.43±0.01 | 0.42±0.01 | 0.40±0.01 | 0.38±0.01 | 0.36±0.01 | 0.34±0.01 |

| 14 | explosive pressure Maximum explosion pressure | MPa | ≤17.0 | |||||

| 15 | Exhaust temperature of each cylinder Each cylinder exhaust temperature | ℃ | ≤450 | |||||

| 16 | Turbine front exhaust temperature Exhaust temperature before turbocharger | ℃ | ≤600 | |||||

| 17 | fuel consumption rate Fuel oil consumption | g/kw. h | 190+5% | |||||

| 18 | Oil consumption rate Lubrication oil consumption | g/kw. h | 1.0 | |||||

| 19 | crank arrangement Crank arrangement | / | 1.8 4.5 + 3.6 2.7 | |||||

| 20 | Fire order Fire order | / | 1-4-7-6-8-5-2-3 | |||||

| 21 | Starting mode Starting method | / | Compressed air start Compressed air starting motor | |||||

| 22 | Fuel supply timing Fuel injection timing | ℃ A | 10~13.5 before top dead center | |||||

| 23 | starting air pressure Starting air pressure | MPa | Starting pressure Max. starting pressure:2.94MPa, starting pressure Min. starting air:1.1MPa | |||||

| 24 | natural gas working pressure | MPa | 0.51 | 0.5 | 0.48 | 0.46 | 0.440.42 | |

| 25 | replacement rate Maximum substitution rate | % | 90 | |||||

| 26 | Dimensions(L×W×H) | mm | 6598.7×2655×4141 | |||||

| 27 | Piston lifting height The lifting height of piston | mm | 3323 | |||||

| 28 | Cylinder liner lifting height The lifting height of cylinder liner | mm | 3798 | |||||

| 29 | Overall machine quality Weight | kg | AboutAbout 47000 | |||||